Image 1 of 1

Image 1 of 1

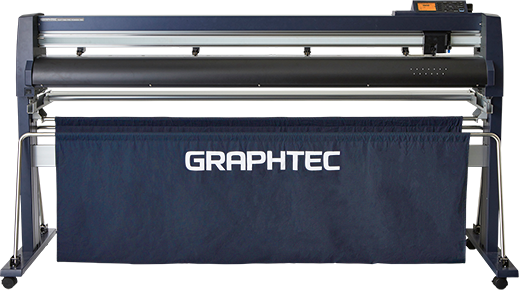

Graphtec Roll Feed Cutting Plotter FC9000 series

A Flagship Model of the World Top Share Cutting Plotter Manufacturer

FC9000 is highly recognized as a cutting plotter with its best quality of finishing solution for a wide range of industries, including wide-format signage, apparel, and automotive applications. Its rigidity and media feeding quality, tool carriage performance have been improved from the previous model to enable more precise cutting.

Our newly developed Advanced Registration Mark Sensing System (ARMS) is installed which will raise the productivity with its variety of functions.

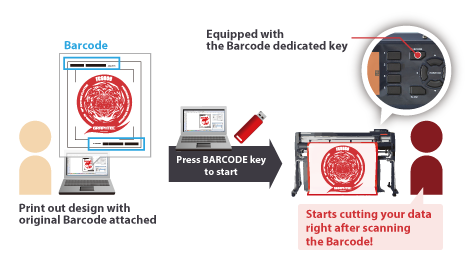

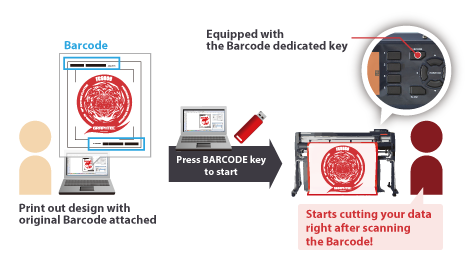

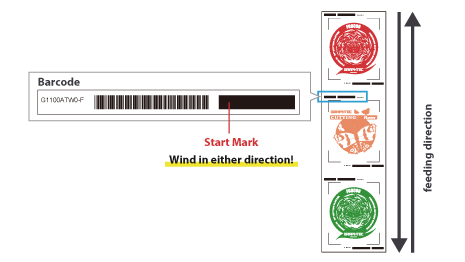

Data Link Function (Barcode Data Management/Continuous Cutting)

By reading the Graphtec original Barcode, FC9000 automatically detects its linked data from PC or USB flash memory. This function is available regardless of which printer or RIP software is used.

- The USB flash memory format only supports FAT32. Please note that NTFS and exFAT are not supported.

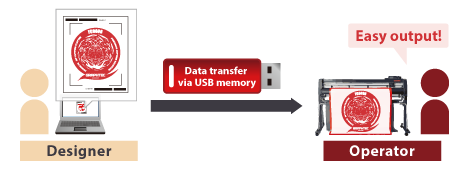

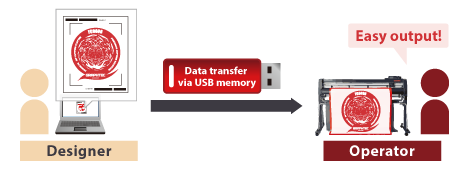

Data output via USB flash memory without PC

When cutting data designed with Cutting Master 5 or Graphtec Studio 2 are saved to USB flash memory, it can be output directly to the cutting plotter by plugging in. This simplified work-flow enables users to operate without a computer.

- The USB flash memory format only supports FAT32. Please note that NTFS and exFAT are not supported.

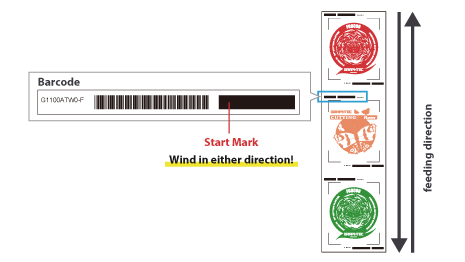

Continuous Cut (Data Link function)

Barcode data management allows cutting different data sequentially by detecting the “Start Mark” of the new Barcode. Sequential Print & Cut process with roll-media is now available.

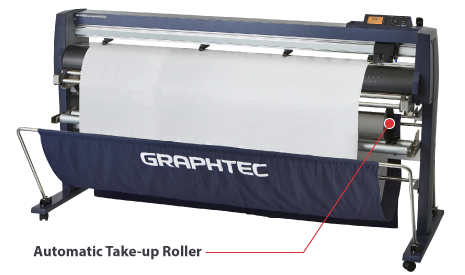

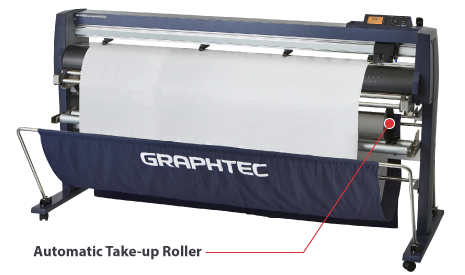

Reliable long-length tracking (Automatic Take-up Roller)

It supports long-length, 15m (50ft) (Operated with Graphtec specified media and conditions.) and makes possible to cut large signs/pops with stable paper carriage and high accurate cutting quality. In addition, if Automatic Take-up Roller as option is equipped to plotter, it becomes possible to automatically wind media and improve your work efficiency.

Automatic Take-up Roller (option)

The media is detected by the ultrasonic sensor and rolled up automatically.

- Corresponding Models: FC9000-140/160

- Guaranteed accuracy length: 20m (Under 1.2m per job)

- Maximum diameter of winding roll: ?180mm

- Winding conditions:

– End face of roll media and end face of paper tube should be aligned.

– Width of roll media should be the same as width of paper tube at winding side. - It cannot be winded if media is folded or overlapped inside the basket.

Software

You can easily create and cut high quality designs with the standard included software.

Specifications

| Item | FC9000-75 | FC9000-100 | FC9000-140 | FC9000-160 |

|---|---|---|---|---|

| Configuration | Grit rolling type | |||

| Drive method | Digital servo drive | |||

| Max. cutting area (W x L) (*1) | 762mm × 50m | 1067mm × 50m | 1372mm × 50m | 1626mm × 50m |

| Cutting area of guaranteed accuracy (*1) | 742mm × 15m |

1047mm × 10m 762mm × 15m |

1352mm × 10m 894mm × 15m |

1607mm × 10m 894mm × 15m |

| Mountable media width (*2) | Min. 50mm | |||

|

Max. 920mm (36.2 inch) |

Max. 1224mm (48.1 inch) |

Max. 1529mm (60.1 inch) |

Max. 1850mm (72.8 inch) |

|

| Mountable roll media diameter | 76 to 200mm (160mm when the optional paper flange (OPH-A21) is installed) | |||

| Mountable roll media mass | 12kg | 16kg | 20kg | 24kg |

| Compatible take-up roll width | – | 200 to 1372mm | 200 to 1626mm | |

| Compatible take-up roll mass | – | 20kg | ||

| Maximum cross cut width | 762mm | 1067mm | 1372mm | 1626mm |

| Max. cutting speed | 1485mm/s at 45° direction | |||

| Axial acceleration | Max. 39.2m/s2 at 45° direction | |||

| Cutting force | Max. 5.88N (600gf) | |||

| Minimum character size | Approx. 3 mm alphanumeric (varies depending on character font and media) | |||

| Mechanical resolution | 0.005mm | |||

| Programmable resolution |

GP-GL?0.1 / 0.05 / 0.025 / 0.01mm? HP-GL™ (*3)?0.025mm |

|||

| Repeatability (*1) | Max. 0.1 mm in plot up to 2 m (Excluding media expansion and contraction) | |||

| Number of push rollers | 2 rollers | 3 rollers | 4 rollers (Max. 5 (option)) | |

| Mountable number of tools | 1 tool (mountable 2 tools (option)) | |||

| Blade types | Supersteel | |||

| Pen types | Oil-based ballpoint pen, Water-based fiber-tip pen | |||

| Media types |

Thickness 0.25mm or less Marking film (PVC film / fluorescence / reflective), Polyester film (on condition), High Intensity reflective film (Diamond grade, Engineer grade) (*4) |

|||

| Display | Graphic type LCD with back-light (240dots × 128dots), supports 10 languages | |||

| Interface | USB 2.0(Full Speed), Ethernet 10BASE-T/100BASE-TX | |||

| Buffer memory | 2MB | |||

| Command sets | GP-GL / HP-GL™ (Set by command or auto-detect) (*3) | |||

| Supported software (*5) |

Graphtec Studio 2, Cutting Master 5, Windows Driver, Graphtec Pro Studio (*6), Graphtec Studio, Cutting Master 4 (*6), |

|||

| Power source | 100 V to 240 V AC, 50 / 60 Hz | |||

| Power consumption | Max. 120 W | |||

| Operating environment | 10 to 35 ºC, 35 to 75 % R.H. (non-condensing) | |||

| Guaranteed accuracy environment | 16 to 32 ºC, 35 to 70 % R.H. (non-condensing) | |||

|

External dimensions (W × D × H) * Includes stand and basket. |

Approx. 1360?1151?1232 mm |

Approx. 1665?1151?1232 mm |

Approx. 1970?1151?1232 mm |

Approx. 2224?1151?1232 mm |

|

Weight (approx.) * Includes stand and basket. |

49 kg | 56 kg |

64.0 kg (80.9kg with installed automatic take-up roller) |

70.0 kg (88.5kg with installed automatic take-up roller) |

| Safety | PSE, UL/cUL, CE mark | |||

| EMC | VCCI Class A, FCC Class A, CE mark | |||

- Operated with Graphtec specified cutting condition and media. For long-length cutting, the basket is used.

- There are conditions for operability when setting media.

- HP-GLTM is a registered trademark of Hewlett-Packard Company.

- CB15UA/CB15UA-K30 blades and reinforced backing sheets are recommended for certain grades of high-intensity reflective film.

- Graphtec does not support software/driver used with operating systems that have become obsolete and are no longer supported by the OS developer.

- It requires an Internet connection in order for activation or registration when starting the software for the first time.

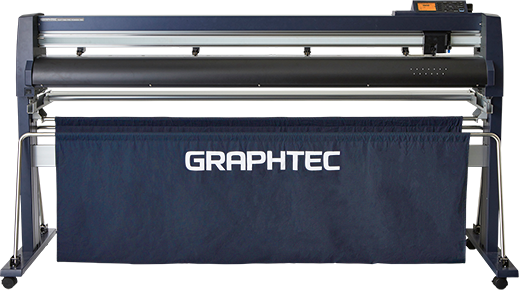

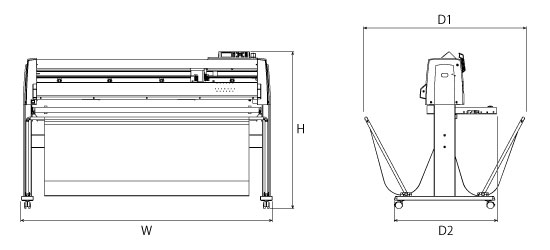

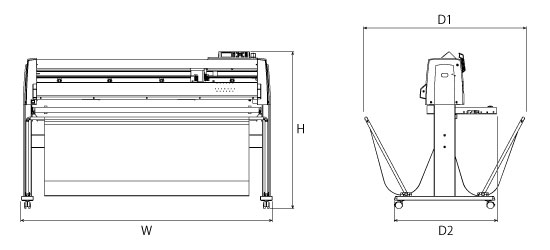

Dimensions

| FC9000-75 | FC9000-100 | FC9000-140 | FC9000-160 | |

|---|---|---|---|---|

|

External dimensions (approx.) (W x D1(D2) x H) |

1360?1151(840)?1232 mm | 1665?1151(840)?1232 mm | 1970?1151(840)?1232 mm | 2224?1151(840)?1232 mm |

- Includes stand and basket.

- Tolerance : +/- 5 mm

Standard accessories

| Item | Q’ty | Description |

|---|---|---|

| Power cord | 1 | The type of cord is different by destination. |

| USB Cable | 1 | 2.9m long |

| Cutting blade holder | 1 | PHP33-CB09N-HS |

| Cutting Blade | 1 | CB09UB-1P |

| Loupe | 1 | PM-CT-001 |

| Stand | 1 | |

| Media Stocker | 1 | |

| Basket | 1 | |

| Flange set | 1 | OPH-A21 (Only in limited sales area.) |

| Printed document | 1 | Setup Manual, Safety Manual |

Option

| Item | Part No. | Description |

|---|---|---|

| Automatic Take-up Roller | OPH-A43 | For FC9000-140 |

| OPH-A44 | For FC9000-160 | |

| Additional push roller kit | OPH-A47 | For FC9000-140 or FC9000-160 |

| 2nd pen holder | ECK0013 | For dual tool configuration (dealer option) |

| Flange | OPH-A21 | Flange for media holding |

A Flagship Model of the World Top Share Cutting Plotter Manufacturer

FC9000 is highly recognized as a cutting plotter with its best quality of finishing solution for a wide range of industries, including wide-format signage, apparel, and automotive applications. Its rigidity and media feeding quality, tool carriage performance have been improved from the previous model to enable more precise cutting.

Our newly developed Advanced Registration Mark Sensing System (ARMS) is installed which will raise the productivity with its variety of functions.

Data Link Function (Barcode Data Management/Continuous Cutting)

By reading the Graphtec original Barcode, FC9000 automatically detects its linked data from PC or USB flash memory. This function is available regardless of which printer or RIP software is used.

- The USB flash memory format only supports FAT32. Please note that NTFS and exFAT are not supported.

Data output via USB flash memory without PC

When cutting data designed with Cutting Master 5 or Graphtec Studio 2 are saved to USB flash memory, it can be output directly to the cutting plotter by plugging in. This simplified work-flow enables users to operate without a computer.

- The USB flash memory format only supports FAT32. Please note that NTFS and exFAT are not supported.

Continuous Cut (Data Link function)

Barcode data management allows cutting different data sequentially by detecting the “Start Mark” of the new Barcode. Sequential Print & Cut process with roll-media is now available.

Reliable long-length tracking (Automatic Take-up Roller)

It supports long-length, 15m (50ft) (Operated with Graphtec specified media and conditions.) and makes possible to cut large signs/pops with stable paper carriage and high accurate cutting quality. In addition, if Automatic Take-up Roller as option is equipped to plotter, it becomes possible to automatically wind media and improve your work efficiency.

Automatic Take-up Roller (option)

The media is detected by the ultrasonic sensor and rolled up automatically.

- Corresponding Models: FC9000-140/160

- Guaranteed accuracy length: 20m (Under 1.2m per job)

- Maximum diameter of winding roll: ?180mm

- Winding conditions:

– End face of roll media and end face of paper tube should be aligned.

– Width of roll media should be the same as width of paper tube at winding side. - It cannot be winded if media is folded or overlapped inside the basket.

Software

You can easily create and cut high quality designs with the standard included software.

Specifications

| Item | FC9000-75 | FC9000-100 | FC9000-140 | FC9000-160 |

|---|---|---|---|---|

| Configuration | Grit rolling type | |||

| Drive method | Digital servo drive | |||

| Max. cutting area (W x L) (*1) | 762mm × 50m | 1067mm × 50m | 1372mm × 50m | 1626mm × 50m |

| Cutting area of guaranteed accuracy (*1) | 742mm × 15m |

1047mm × 10m 762mm × 15m |

1352mm × 10m 894mm × 15m |

1607mm × 10m 894mm × 15m |

| Mountable media width (*2) | Min. 50mm | |||

|

Max. 920mm (36.2 inch) |

Max. 1224mm (48.1 inch) |

Max. 1529mm (60.1 inch) |

Max. 1850mm (72.8 inch) |

|

| Mountable roll media diameter | 76 to 200mm (160mm when the optional paper flange (OPH-A21) is installed) | |||

| Mountable roll media mass | 12kg | 16kg | 20kg | 24kg |

| Compatible take-up roll width | – | 200 to 1372mm | 200 to 1626mm | |

| Compatible take-up roll mass | – | 20kg | ||

| Maximum cross cut width | 762mm | 1067mm | 1372mm | 1626mm |

| Max. cutting speed | 1485mm/s at 45° direction | |||

| Axial acceleration | Max. 39.2m/s2 at 45° direction | |||

| Cutting force | Max. 5.88N (600gf) | |||

| Minimum character size | Approx. 3 mm alphanumeric (varies depending on character font and media) | |||

| Mechanical resolution | 0.005mm | |||

| Programmable resolution |

GP-GL?0.1 / 0.05 / 0.025 / 0.01mm? HP-GL™ (*3)?0.025mm |

|||

| Repeatability (*1) | Max. 0.1 mm in plot up to 2 m (Excluding media expansion and contraction) | |||

| Number of push rollers | 2 rollers | 3 rollers | 4 rollers (Max. 5 (option)) | |

| Mountable number of tools | 1 tool (mountable 2 tools (option)) | |||

| Blade types | Supersteel | |||

| Pen types | Oil-based ballpoint pen, Water-based fiber-tip pen | |||

| Media types |

Thickness 0.25mm or less Marking film (PVC film / fluorescence / reflective), Polyester film (on condition), High Intensity reflective film (Diamond grade, Engineer grade) (*4) |

|||

| Display | Graphic type LCD with back-light (240dots × 128dots), supports 10 languages | |||

| Interface | USB 2.0(Full Speed), Ethernet 10BASE-T/100BASE-TX | |||

| Buffer memory | 2MB | |||

| Command sets | GP-GL / HP-GL™ (Set by command or auto-detect) (*3) | |||

| Supported software (*5) |

Graphtec Studio 2, Cutting Master 5, Windows Driver, Graphtec Pro Studio (*6), Graphtec Studio, Cutting Master 4 (*6), |

|||

| Power source | 100 V to 240 V AC, 50 / 60 Hz | |||

| Power consumption | Max. 120 W | |||

| Operating environment | 10 to 35 ºC, 35 to 75 % R.H. (non-condensing) | |||

| Guaranteed accuracy environment | 16 to 32 ºC, 35 to 70 % R.H. (non-condensing) | |||

|

External dimensions (W × D × H) * Includes stand and basket. |

Approx. 1360?1151?1232 mm |

Approx. 1665?1151?1232 mm |

Approx. 1970?1151?1232 mm |

Approx. 2224?1151?1232 mm |

|

Weight (approx.) * Includes stand and basket. |

49 kg | 56 kg |

64.0 kg (80.9kg with installed automatic take-up roller) |

70.0 kg (88.5kg with installed automatic take-up roller) |

| Safety | PSE, UL/cUL, CE mark | |||

| EMC | VCCI Class A, FCC Class A, CE mark | |||

- Operated with Graphtec specified cutting condition and media. For long-length cutting, the basket is used.

- There are conditions for operability when setting media.

- HP-GLTM is a registered trademark of Hewlett-Packard Company.

- CB15UA/CB15UA-K30 blades and reinforced backing sheets are recommended for certain grades of high-intensity reflective film.

- Graphtec does not support software/driver used with operating systems that have become obsolete and are no longer supported by the OS developer.

- It requires an Internet connection in order for activation or registration when starting the software for the first time.

Dimensions

| FC9000-75 | FC9000-100 | FC9000-140 | FC9000-160 | |

|---|---|---|---|---|

|

External dimensions (approx.) (W x D1(D2) x H) |

1360?1151(840)?1232 mm | 1665?1151(840)?1232 mm | 1970?1151(840)?1232 mm | 2224?1151(840)?1232 mm |

- Includes stand and basket.

- Tolerance : +/- 5 mm

Standard accessories

| Item | Q’ty | Description |

|---|---|---|

| Power cord | 1 | The type of cord is different by destination. |

| USB Cable | 1 | 2.9m long |

| Cutting blade holder | 1 | PHP33-CB09N-HS |

| Cutting Blade | 1 | CB09UB-1P |

| Loupe | 1 | PM-CT-001 |

| Stand | 1 | |

| Media Stocker | 1 | |

| Basket | 1 | |

| Flange set | 1 | OPH-A21 (Only in limited sales area.) |

| Printed document | 1 | Setup Manual, Safety Manual |

Option

| Item | Part No. | Description |

|---|---|---|

| Automatic Take-up Roller | OPH-A43 | For FC9000-140 |

| OPH-A44 | For FC9000-160 | |

| Additional push roller kit | OPH-A47 | For FC9000-140 or FC9000-160 |

| 2nd pen holder | ECK0013 | For dual tool configuration (dealer option) |

| Flange | OPH-A21 | Flange for media holding |