Image 1 of 1

Image 1 of 1

Graphtec Garment Pattern Cutting Plotter CE7000-130AP

High-quality and High-speed Cutter for Apparel Applications

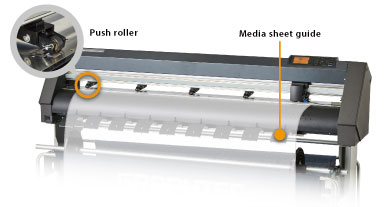

CE7000-130AP is a high-speed, professional cutting plotter designed specifically as an output machine device for apparel CAD systems.

Dual tool configuration has been installed to improve the production efficiency, and the cutting speed of perforation cut has been faster compared to the previous model. It also features an easy-to-use menu navigation system with eight groups of preset conditions which facilitates instantaneous recall of pre-programmed job-specific plotter setups.

Dual tool configuration for cutting and plotting

It holds both a pen and a blade.

The pen is for plotting and detailing graded patterns with seams, text, notches, grain direction, etc. The blade is to make the perforated cut of the pattern outline.

The tool is automatically switched for cutting and plotting as needed, ensuring a high quality pattern and maximum productivity.

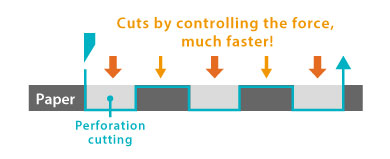

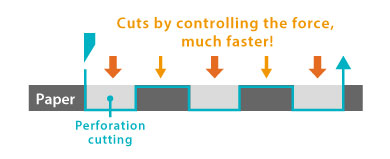

Enhanced speed when perforation cut

Perforation cutting is performed by controlling the cutting force instead of blade up/down movements, dramatically increasing throughput.

The force is controlled by the design software using a new command.

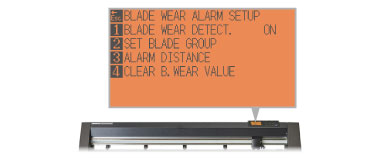

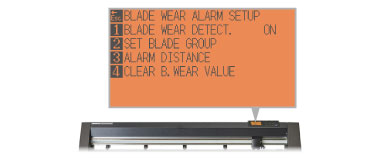

Blade / Pen wear level alarm function

Able to measure cutting distance of consumables such as blades and pens, and set conditions for tool replacement.

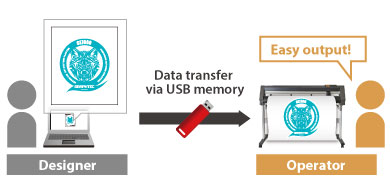

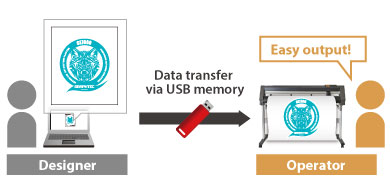

Data output via USB flash memory without PC

USB memory reading port enables users to output data via USB flash memory without PC or dedicated software.

- The USB memory format only supports FAT32.

Please note that NTFS and exFAT are not supported.

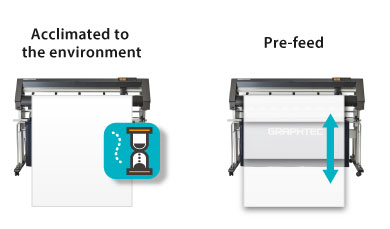

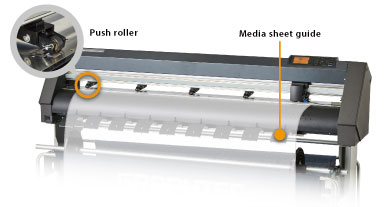

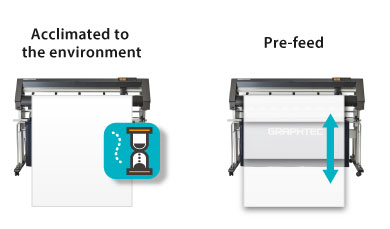

High adaptability to the operating environment

The design of the media feed system ensures that loaded media is acclimated to the ambient temperature and humidity before plotting or cutting. The user-selectable media pre-feed function sets two outer tracks, enhancing media handling.

Together, these two media feed elements ensure reliable cutting and plotting quality within the desired operating environment.

Specifications

| Item | Description |

|---|---|

| Configuration | Grit rolling type |

| Drive method | Digital servo drive |

| Max. cutting area (W x L) (*1) | 1220 mm × 50 m |

| Cutting area of guaranteed accuracy (*1) | 1200 mm × 3 m |

| Mountable media width (*2) | Min. 594 mm |

| Max. 1321 mm | |

| Mountable roll media inside-diameter | 3 inches |

| Mountable roll media outside-diameter | Max. 200 mm |

| Mountable roll media mass | Max. 20 kg |

| Number of push rollers | 5 rollers |

| Cutting speed | Max. 600 mm/s at all direction |

| Cutting force | Max. 4.41N (450gf ) |

| Mechanical resolution | 0.005 mm |

| Programmable resolution |

GP-GL?0.1 / 0.05 / 0.025 / 0.01 mm HP-GLTM (*3)?0.025mm |

| Repeatability | Max. 0.1 mm in plot up to 2 m (*1)(*4) |

| Mountable number of tools | 2 tool |

| Pen types | Oil-based ballpoint pen, Water-based fiber-tip pen |

| Interface | USB 2.0 (Full Speed), Ethernet 10BASE-T/100BASE-TX |

| Buffer memory | 2MB |

| Command sets | GP-GL / HP-GLTM (*3) (Set by command) |

| Display | Graphic type LCD with back-light (240dots x 128dots), supports 10 languages |

| Power source | 100V to 120V AC, 200V to 240V AC, 50/60 Hz (Auto switch) |

| Power consumption | 100W |

| Operating environment | 10 to 35 ºC, 35 to 75 % R.H. (non-condensing) |

| Guaranteed accuracy environment | 18 to 28 ºC, 40 to 65 % R.H. (non-condensing) |

| External dimensions (W x D x H) | Approx. 1704 × 1148 × 1215 mm (Including Stand and Basket) |

| Weight | Approx. 60kg (Including Stand and Basket) |

| Compatible OS (*5) | Windows 11 / 10 / 8.1 |

- This is the specialized model for high grade fine paper for apparel use.

- Operated with Graphtec specified cutting condition and media.

- Mountable media width. The minimum paper width with guaranteed accuracy is the width when the push rollers are placed on 5mm inside of both side of media. Sheet paper (cut paper) is not guaranteed.

- HP-GL™ is a registered trademark of Hewlett-Packard Company.

- Graphtec specified Mylar film is used to check the accuracy.

- Graphtec does not support software/driver used with operating systems that have become obsolete and are no longer supported by the OS developer.

Dimensions

- Unit : mm, Tolerance : ± 5mm

Standard accessories

| Item | Description | Q’ty |

|---|---|---|

| Power cord | The type of cord is different by destination. | 1 |

| USB Cable | 2.9m long | 1 |

| Cutter Blade Holder | PHP33-CB09N-HS | 1 |

| Cutter Blade | CB09UB-1 | 1 |

| Loupe | PM-CT-001 | 1 |

| Stand for CE7000-130AP | ST0121, Stand with Basket | 1 |

| Ballpoint pen holder | PHP34-BALL | 1 |

| Oil-based ballpoint pen | KB700-BK (Black) | 1 |

| CD-ROM | User manual, Windows driver | 1 |

| Printed document | Setup Manual, Cutter Blade Manual and Safety Manual | 1 |

- Please read Cutter Blade Manual before use.

High-quality and High-speed Cutter for Apparel Applications

CE7000-130AP is a high-speed, professional cutting plotter designed specifically as an output machine device for apparel CAD systems.

Dual tool configuration has been installed to improve the production efficiency, and the cutting speed of perforation cut has been faster compared to the previous model. It also features an easy-to-use menu navigation system with eight groups of preset conditions which facilitates instantaneous recall of pre-programmed job-specific plotter setups.

Dual tool configuration for cutting and plotting

It holds both a pen and a blade.

The pen is for plotting and detailing graded patterns with seams, text, notches, grain direction, etc. The blade is to make the perforated cut of the pattern outline.

The tool is automatically switched for cutting and plotting as needed, ensuring a high quality pattern and maximum productivity.

Enhanced speed when perforation cut

Perforation cutting is performed by controlling the cutting force instead of blade up/down movements, dramatically increasing throughput.

The force is controlled by the design software using a new command.

Blade / Pen wear level alarm function

Able to measure cutting distance of consumables such as blades and pens, and set conditions for tool replacement.

Data output via USB flash memory without PC

USB memory reading port enables users to output data via USB flash memory without PC or dedicated software.

- The USB memory format only supports FAT32.

Please note that NTFS and exFAT are not supported.

High adaptability to the operating environment

The design of the media feed system ensures that loaded media is acclimated to the ambient temperature and humidity before plotting or cutting. The user-selectable media pre-feed function sets two outer tracks, enhancing media handling.

Together, these two media feed elements ensure reliable cutting and plotting quality within the desired operating environment.

Specifications

| Item | Description |

|---|---|

| Configuration | Grit rolling type |

| Drive method | Digital servo drive |

| Max. cutting area (W x L) (*1) | 1220 mm × 50 m |

| Cutting area of guaranteed accuracy (*1) | 1200 mm × 3 m |

| Mountable media width (*2) | Min. 594 mm |

| Max. 1321 mm | |

| Mountable roll media inside-diameter | 3 inches |

| Mountable roll media outside-diameter | Max. 200 mm |

| Mountable roll media mass | Max. 20 kg |

| Number of push rollers | 5 rollers |

| Cutting speed | Max. 600 mm/s at all direction |

| Cutting force | Max. 4.41N (450gf ) |

| Mechanical resolution | 0.005 mm |

| Programmable resolution |

GP-GL?0.1 / 0.05 / 0.025 / 0.01 mm HP-GLTM (*3)?0.025mm |

| Repeatability | Max. 0.1 mm in plot up to 2 m (*1)(*4) |

| Mountable number of tools | 2 tool |

| Pen types | Oil-based ballpoint pen, Water-based fiber-tip pen |

| Interface | USB 2.0 (Full Speed), Ethernet 10BASE-T/100BASE-TX |

| Buffer memory | 2MB |

| Command sets | GP-GL / HP-GLTM (*3) (Set by command) |

| Display | Graphic type LCD with back-light (240dots x 128dots), supports 10 languages |

| Power source | 100V to 120V AC, 200V to 240V AC, 50/60 Hz (Auto switch) |

| Power consumption | 100W |

| Operating environment | 10 to 35 ºC, 35 to 75 % R.H. (non-condensing) |

| Guaranteed accuracy environment | 18 to 28 ºC, 40 to 65 % R.H. (non-condensing) |

| External dimensions (W x D x H) | Approx. 1704 × 1148 × 1215 mm (Including Stand and Basket) |

| Weight | Approx. 60kg (Including Stand and Basket) |

| Compatible OS (*5) | Windows 11 / 10 / 8.1 |

- This is the specialized model for high grade fine paper for apparel use.

- Operated with Graphtec specified cutting condition and media.

- Mountable media width. The minimum paper width with guaranteed accuracy is the width when the push rollers are placed on 5mm inside of both side of media. Sheet paper (cut paper) is not guaranteed.

- HP-GL™ is a registered trademark of Hewlett-Packard Company.

- Graphtec specified Mylar film is used to check the accuracy.

- Graphtec does not support software/driver used with operating systems that have become obsolete and are no longer supported by the OS developer.

Dimensions

- Unit : mm, Tolerance : ± 5mm

Standard accessories

| Item | Description | Q’ty |

|---|---|---|

| Power cord | The type of cord is different by destination. | 1 |

| USB Cable | 2.9m long | 1 |

| Cutter Blade Holder | PHP33-CB09N-HS | 1 |

| Cutter Blade | CB09UB-1 | 1 |

| Loupe | PM-CT-001 | 1 |

| Stand for CE7000-130AP | ST0121, Stand with Basket | 1 |

| Ballpoint pen holder | PHP34-BALL | 1 |

| Oil-based ballpoint pen | KB700-BK (Black) | 1 |

| CD-ROM | User manual, Windows driver | 1 |

| Printed document | Setup Manual, Cutter Blade Manual and Safety Manual | 1 |

- Please read Cutter Blade Manual before use.